How the Best Baseboard Heater Covers Are Made

The best Baseboard Heater Covers are totally custom and made exactly to any size and layout needed.

Any length, any height, any depth, straight or around corners.

The best covers come in a variety of styles and materials to suite your home and your taste.

They look Great, perform great, and are easy to install…no compromises!

That is what we offerat Sunrise Woodwork.

It begins with the order form, which allows you to enter all the necessary details quickly and precisely.

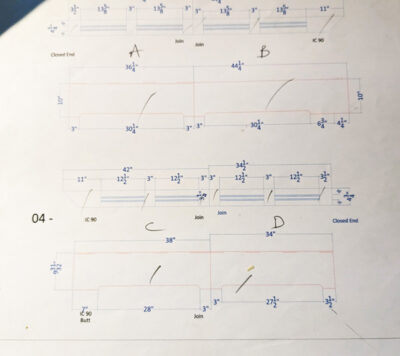

The information you provide on the order form is used to make a detailed drawing. We can make a unique size cover to your exact needs.

Because all design work and fabrication is done in our shop we can provide a beautiful solution to your problem.

The best wood baseboard heater covers are made by skilled workers in a cabinet shop, not a factory. Each of the many steps are carefully done by one or two craftsmen who oversee the entire piece from start to finish. This assures a flawless job. They are not made on an assembly line where defects can slip through.

At Sunrise Woodwork we begin with rough lumber for the tops. Oak, Cherry, Mahogany, for a clear lacquer finish, or poplar if it is to be painted.

It is cut to size, dressed to thickness, and made ready to be assembled.

Because we start with a rough board and full sheets of plywood, we can make our covers to any size and offer several styles and material options.

The fronts of the baseboard covers are made with top quality cabinet grade plywood with select grade veneers. For a painted finish we use fiberboard, very stable, they stay flat and take a beautiful finish.

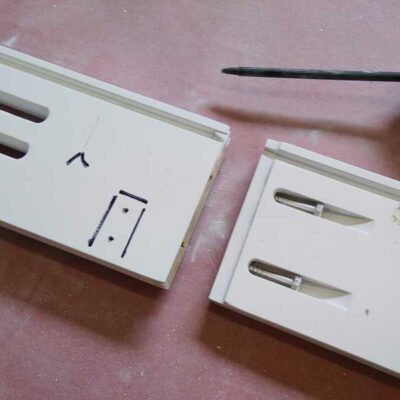

The vent slots on the bottom of the cover line up with the vents on the top and are all spaced evenly down the length of your wall for a nice, balanced look.

After the top sections are glued together finger joints are made on the ends so that many sections can easily and accurately be joined together to make any length needed.

Also, the front edge is shaped, the edges of the vent slots are gently rounded, and everything is sanded smooth.

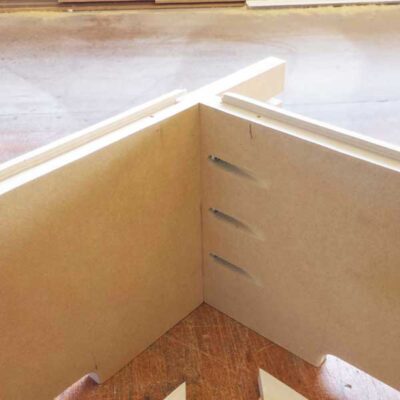

Ease of assembly is important and the covers from Sunrise Woodwork go together in a snap.

All the parts line up automatically with tongue and grooves and finger joints.

The parts simply screw together using the square drive bit that is included in each order.

Everything is pre-assembled in the shop to make sure everything is correct.

A great finish is a big part of the work in making a custom wood heater cover.

First the raw wood is sanded smooth, then both sides of all pieces are sprayed with either lacquer primer or clear lacquer.

When the first coat is dry it must be sanded smooth and then the pieces are sprayed again.

If there are any imperfections, they are corrected and sprayed again.

When the primer is perfect the finish coat can be applied.

If you are interested in having custom wood baseboard heater covers made for your home, you can learn more about it here:

If you would like to discuss your project, you can send me an email : tom@sunrisewoodwork.com

You can text me at: 845.987.0580

You can even just ring me up at the number to talk, I will answer the call.

I am very happy to work with you to sort out all details no matter how unusual your project may be. My customers enjoy one on one attention.